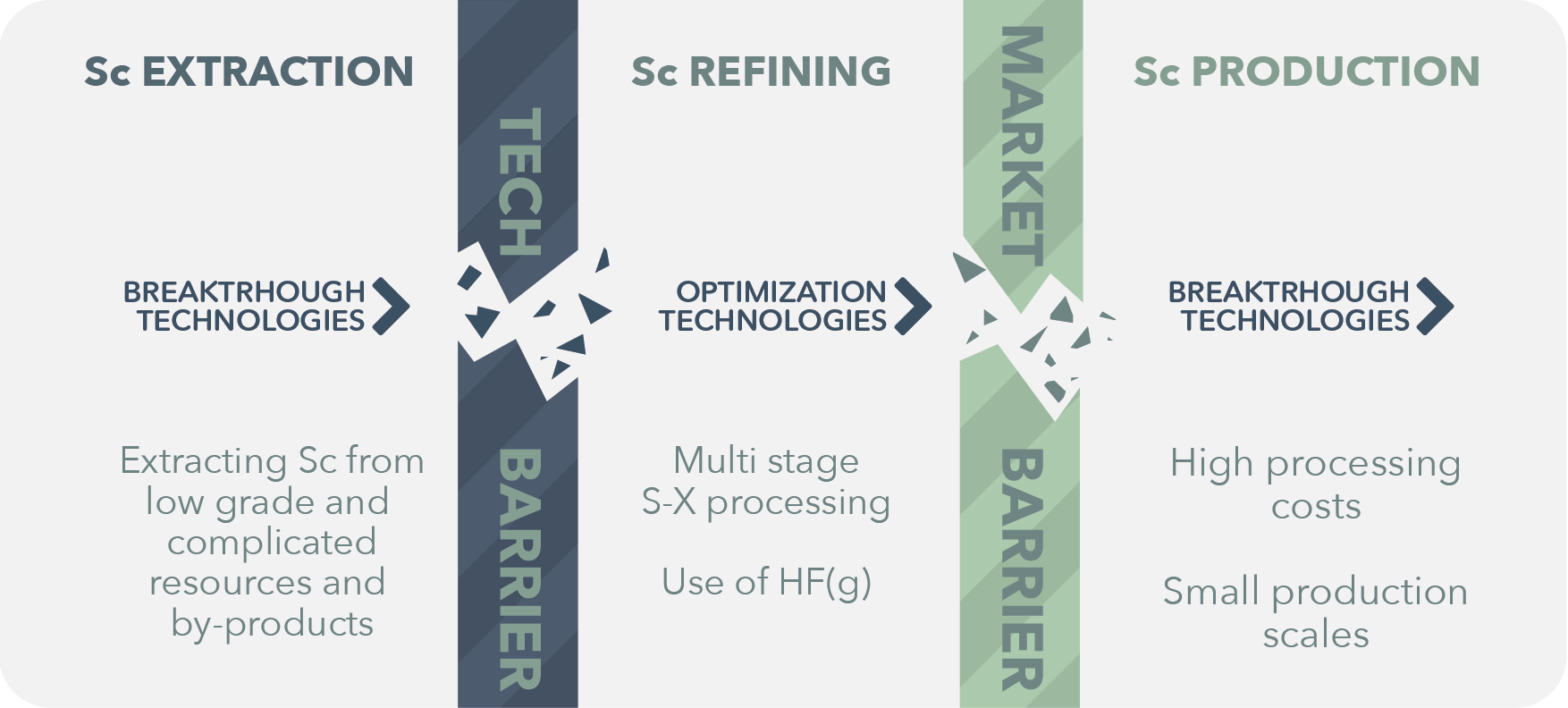

The main aim of SCALE is the efficient exploitation of EU high concentration scandium containing resources including bauxite residues (100-150 ppm) resulting from alumina production and acid wastes (50-100 ppm) from TiO2 pigment production to develop a stable and secure EU scandium supply chain to serve the needs of EU aerospace and high tech industry. This will be achieved through the development of a number of innovative extraction, separation, refining and alloying technologies that will be validated in an appropriate laboratory and bench scale environment to prove their technical and economic feasibility.

Produce commercial Scandium concentrates (at least 20% wt) from 2 European metallurgical by-products with innovative Sc selective technologies.

Starting from Bauxite Residue of the European alumina industry (which contain 80 (Hungarian BR) to 130 (Greek BR) mg/kg of Sc on a dry basis):

- Scandium ions are leached in SCALE with conventional and innovative reagents to form dilute pregnant liquid solution (PLS) with 10-100 mg/L Sc; the process is selective towards Sc leaching avoiding dissolution of major BR components like iron, aluminium, titanium and silicon. [Deliverable D1.1]

- The dilute PLS is upgraded to an at least 20%wt Sc2O3 concentrate through the use of the innovative ‘SIR’ ion-exchange technology, developed in SCALE. [Deliverable D1.3]

- The process is zero-waste as the liquid by-product of the process (raffinate) is a 0.5 gr/kg REE containing PLS ; the solid by-product of the process is a 60% wt iron oxide concentrate which is used for pig-iron and slag wool production [Deliverable D2.1]

- The process is validated in SCALE at the AoG alumina refinery and aluminium smelter plant, achieving TRL 5, through the production of at least 1kg of 20%wt Sc2O3 concentrate [Deliverable D2.2]

Starting from the acid waste of TiO2 pigment industry, Scandium is extracted from either liquid or solid by-product:

- From the acid waste solution (which contains from 40 – 50 mg/L of Sc) Scandium is extracted directly with the use of the innovative acid nanofiltration technology, developed in SCALE. [Deliverable D1.2]

- The innovative acid nanofiltration technology is validated at the TRONOX plant achieving TRL 5 with at least 100 h of operation with ‘fresh’ waste solution [Deliverable D2.3]

- From the filter cake (which contains 100-150 mg/kg of Sc and is produced during acid waste solution neutralization at TRONOX) Scandium is extracted selectively and the dilute PLS produced is upgraded to an at least 20%wt Sc2O3 concentrate using SIR technology. [Deliverable D1.2]

Refine Scandium concentrates to (at least 99% purity) Sc2O3 and ScF3 compounds with innovative technologies

- An at least 99%wt Sc2O3 is produced from Sc-concentrate through an optimization of the established solvent extraction process, resulting in at least 10% reduction in processing costs. [Deliverable D3.1]

- An at least 99%wt ScF3 is produced directly from Sc-concentrate, effectively by-passing the production of Sc2O3, resulting in an overall at least 50% reduction in processing costs. [Deliverable D3.2]

Reduce Sc compounds to Sc metal and Sc metal master alloys for end-user applications with innovative technologies

Three different technologies are developed in SCALE where

- Metallic Sc (at least 98% wt purity) and Al-Sc master alloy (2%wt in Sc) are produced with the use of calciothermic reduction of ScF3 and ScF3 /Al2O [Deliverable D4.1]

- Metallic Sc (at least 98% wt purity) and Al-Sc master alloy (2%wt in Sc) are produced with the use of molten salt electrolysis from Sc2O [Deliverable D4.2]

- Metallic Sc (at least 98% wt purity) is produced from Sc-salts through electrowining in Ionic Liquid solutions at near room temperatures. [Deliverable D4.3]

- Optimum technology is scaled up in larger reactor and is validated through the production of at least 1 kg of Al-Sc master alloy (2%wt Sc) achieving TRL 5. The alloy produced is further evaluated through its use in established 3D printing technology of AIRBUS. [Deliverable D4.4]

Assess the sustainability of the developed technologies

Physical, chemical, biological and ecotoxicological characterization of chemicals used [Deliverable D5.3]

- Life Cycle Analysis and Life Cycle Cost analysis of technologies under application scales for mass flows and production processes [Deliverable D5.2]

- Cost and techno-economic assessment of developed technologies [Deliverable D5.3]

- Social Acceptance through appropriate communication activities [Deliverable D8.3]

Establish the foundation for a European Sc industry

SCALE establishes the basis for a European Sc extraction and processing industry by:

- Developing a Scandium and other Critical Raw Material inventory of relevant industrial residues. [Deliverable 1]

- A roadmap, connecting current and future European Scandium demand, emerging applications and potential European supply. [Deliverable D7.1]

- A technology communication and exploitation plan, making the Scandium resource and its potential known to European industrial stakeholders, legislators, researchers and citizens. [Deliverable D8.5]

- Establishing a Cluster in this field to organise the actors all along the value chain in Europe [Deliverable D6.2] as well as networking with international RTD initiatives. [Deliverable D6.3]

Scandium is a chemical element with symbol Sc and atomic number 21. A silvery-white metallic d-block element, it was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.

Scandium is a chemical element with symbol Sc and atomic number 21. A silvery-white metallic d-block element, it was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.