PROJECT PROGRESS

Optimum metal/alloy production technology for scale up

Installation Prototype plant in AoG

Scandium RTD visibility

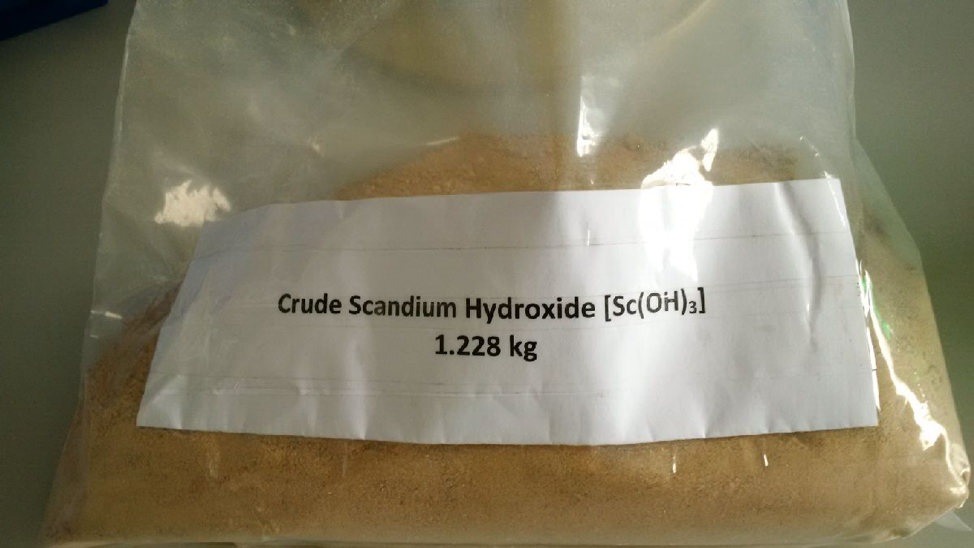

Selective leaching of Sc against iron, aluminum and titanium has been achieved from Greek bauxite residues using different innovative technologies (leaching with mineral acid, leaching with Ionic Liquids and mechanochemical leaching with mineral acid) . Resulting leach solutions with as low as 6 mg/lt in Sc have been utilized in the II-VI SIR process, to produce a concentrates with more than 60gr/kg Sc2O3.

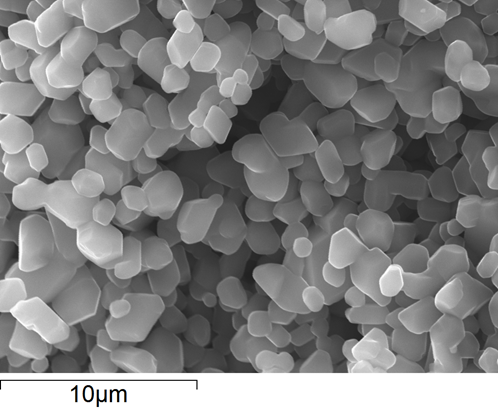

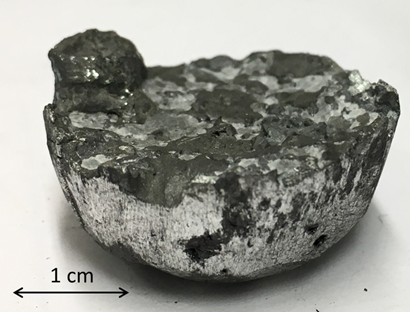

Three technologies have provided breakthrough results: Lab scale aluminothermic production of Al- Sc master alloy from ScF3. Bulk Al-Sc alloys with contents up to 27 wt.-% Sc could be produced with no other impurities, at a Sc reduction yield of 77 %. Using a modified Hall-Heroult process, direct production of Al-Sc alloy from Sc2O3 was achieved in a cell setup used currently in the primary aluminium industry. The aluminium metal product obtained contained 2.6 wt% Sc, and the current efficiency of the process being of ca. 85 %. Direct metallic Sc production from ScCl3 dissolved in an ionic liquid was achieved at 30oC electrolysis temperature. 0,013g of Sc were

Scandium is a chemical element with symbol Sc and atomic number 21. A silvery-white metallic d-block element, it was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.

Scandium is a chemical element with symbol Sc and atomic number 21. A silvery-white metallic d-block element, it was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.