New

Hydrometallurgical Processing of Scandium Concentrate, December 2019

Purpose of developing and optimizing a sustainable solvent extraction process operation was to separate and purify scandium from a scandium concentrate generated in the II VI SIR Plant. The II-VI technology includes a selective-ion recovery (SIR) that is using a new composite extractant-enhanced ion-exchange resin to extract scandium from acidic solutions or slurries. The initial effluent solution of about 2m²

SCALE project, a H2020 success story

The SCALE project was selected as a Horizon 2020 success story, and presented as such, at the 2019 Raw Materials Week in Brussels. In addition to a brief explanation of the project, its technology and its objectives, topics such as its replicability and the use of different feedstocks, i.e. non-EU bauxite residues, were discussed in an interactive session with the

SCALE 2nd project review completed with success

The 6th progress meeting and 2nd project review of the SCALE project took place in Brussels on the 16 and 17th of October 2019. The technical progress of the project over the last 18 months was reviewed. The SCALE project now enters its final year, having successfully achieved all its technological research objectives and moves forward to make its technological demonstrations.

Joint MEAB-KTH pilot tests underway in WP3

The pilot test, run jointly by MEAB and KTH, aims to obtain ScF3 with a purity of at least 99% after crystallisation from scandium strip liquor.

SCALE participated in MIREU’s SLO workshop

SCALE was presented at the 3rd SLO Workshop Ensuring SLO is Adaptive and Resilient (5-6 June 2019, Brussels, Belgium), within the context of the MIREU project. The relevant lessons with regard to SLO, as well as additional aspects which affect the market deployment of the new technologies developed by SCALE, were presented to and discussed with an audience comprising other Eu projects,

Bauxite Residue on focus in the newest JRC report

Latest JRC science for policy report includes special chapter on the Bauxite Residue handling and recycling. The report, titled Recovery of critical and other raw materials from mining waste and landfills, focuses on the untapped potential to extract strategic raw materials from mining waste and landfills in Europe. The chapter, titled “Bauxite Residue as a resource in Europe”, gives the context of

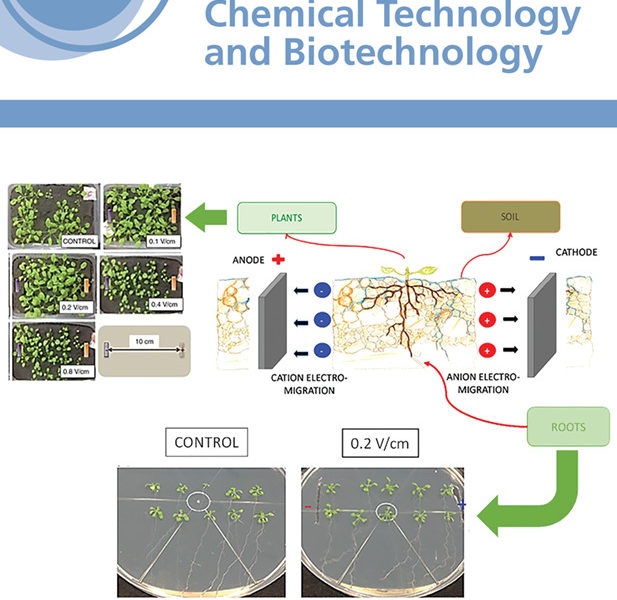

SCALE research article is one of the most downloaded!

The paper Re-using bauxite residues: benefits beyond (critical raw) material recovery, published in Journal of Chemical Technology & Biotechnology,s one of the journal’s top downloaded recent papers! See more SCALE publications

The 5th progress meeting took place in Basel

The 5th Progress meeting was held at FHNW in Basel, Switzerland on the 28-29 May 2019

European First: Solvent Impregnated Resin (SIR) Processing of Scandium Concentrate, April 2019

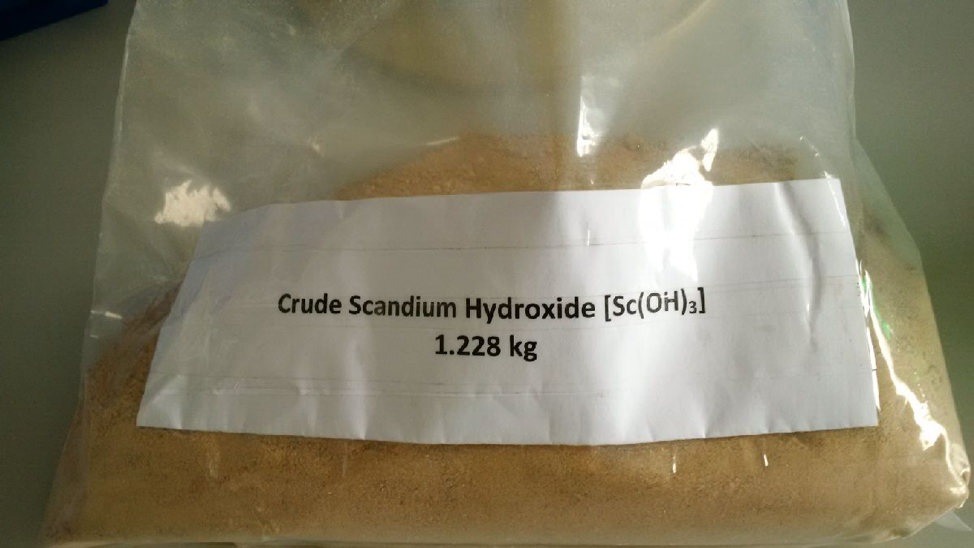

II-VI has successfully demonstrated its SIR process in pilot scale by processing 1.9 m3 of acid waste stream from TRONOX and producing 1.3 kg of crude scandium oxide concentrate. This is the first case of Sc oxide production from European industrial waste stream. The SIR pilot plant was subsequently been transferred to Mytilineos – Aluminium of Greece refinery where it

MEAB Solvent Extraction Bench Scale Operation Under Way, April 2019

MEAB GmbH will set-up their solvent extraction bench scale demonstration plant in Aachen, Germany. Working with scandium hydroxide produced from Tronox acid waste solution using II-VI SIR pilot plant, they will conduct main operation steps: 1) Dissolution and impurity hydrolysis, 2) Scandium solvent extraction, and 3) Precipitation of ammonium-scandium-hexafluoride by anti-solvent addition. This method has been developed by MEAB engineers

Scandium is a chemical element with symbol Sc and atomic number 21. A silvery-white metallic d-block element, it was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.

Scandium is a chemical element with symbol Sc and atomic number 21. A silvery-white metallic d-block element, it was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.