Scale

The 5th progress meeting took place in Basel

The 5th Progress meeting was held at FHNW in Basel, Switzerland on the 28-29 May 2019

European First: Solvent Impregnated Resin (SIR) Processing of Scandium Concentrate, April 2019

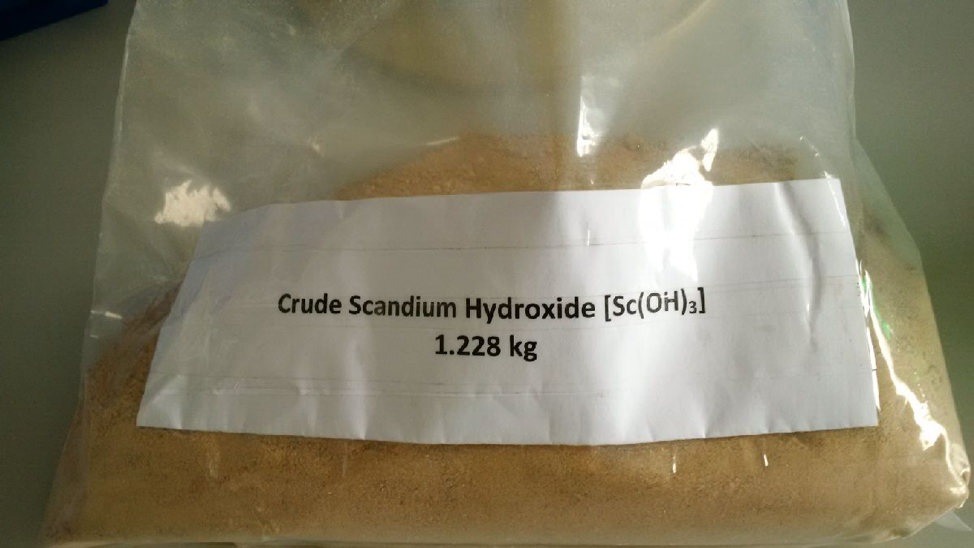

II-VI has successfully demonstrated its SIR process in pilot scale by processing 1.9 m3 of acid waste stream from TRONOX and producing 1.3 kg of crude scandium oxide concentrate. This is the first case of Sc oxide production from European industrial waste stream. The SIR pilot plant was subsequently been transferred to Mytilineos – Aluminium of Greece refinery where it

MEAB Solvent Extraction Bench Scale Operation Under Way, April 2019

MEAB GmbH will set-up their solvent extraction bench scale demonstration plant in Aachen, Germany. Working with scandium hydroxide produced from Tronox acid waste solution using II-VI SIR pilot plant, they will conduct main operation steps: 1) Dissolution and impurity hydrolysis, 2) Scandium solvent extraction, and 3) Precipitation of ammonium-scandium-hexafluoride by anti-solvent addition. This method has been developed by MEAB engineers

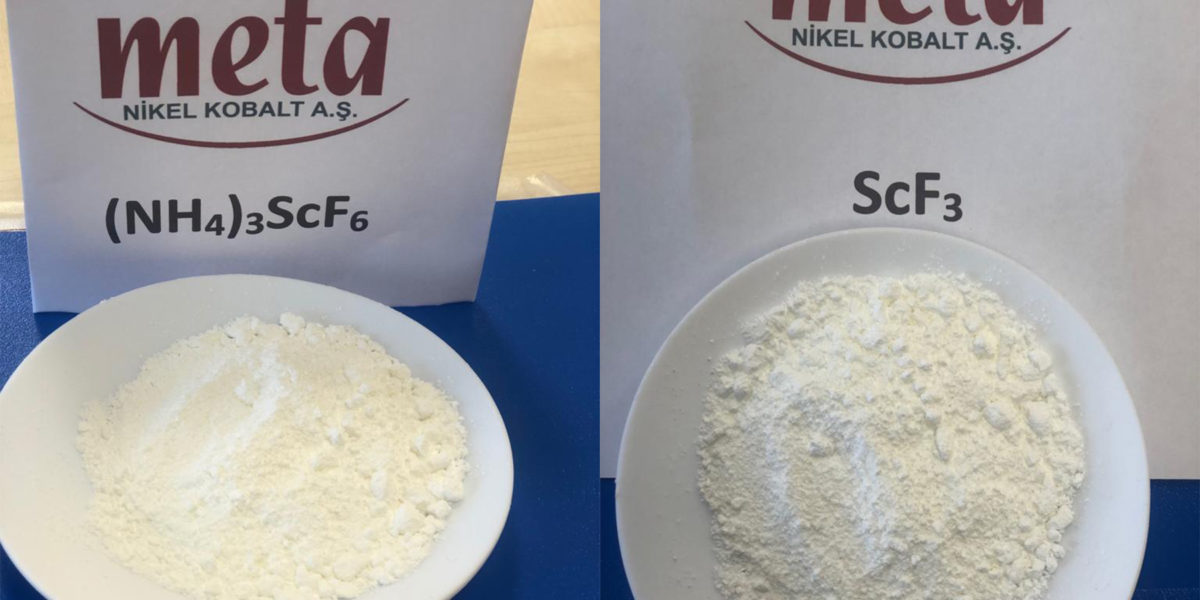

META Scandium products

META Nikel-Kobalt A.Ş produced their first Scandium product using MEAB’s solvent extraction mixer-settler mini-pilot plant. Scandium was separated from a Nickel and Cobalt HPAL production plant in Gördes, Turkey. META produced about 600 grams of Sc product in the form of Ammonium-Scandium-Hexafuoride ((NH4)3ScF6). After calcination, they also converted (NH4)3ScF6 to Scandium fluoride (ScF3) suitable for molten salt or metallothermic reduction.

SCALE research awarded the 2019 Light Metals Subject Award

A team from NTUA Laboratory of Metallurgy and Mytilineos, Metallurgy Business Unit has been awarded the 2019 Light Metals Subject Award – Alumina/Bauxite for its innovative work “Developing a new process for selective extraction of Rare Earth Element from Bauxite Residue based on factionlized ionic liquids”.

How the SCALE pilot turns trash into treasure

The SCALE pilot plant uses ionic liquid to extract rare earth elements from the bauxite residue (red mud) of alumina production.

Critical raw materials & scandium inventory workshops concluded

The Critical raw materials data management & European scandium inventory workshops took place with great success, in Berlin, Germany, on 26-27 November 2018. The workshops were co-organised by SCALE and the German Federal Institute for Materials Research and Testing (BAM). To download the presentations and view photos from the events, please visit the Workshop Results page.

The 4th progress meeting took place in Berlin

The 4th progress meeting was held at BAM in Berlin on the 28th of November. At the 2 year mark of the project, all research streams have produced significant results and the SCALE pilot facilities are being commissioned according to plan.

SCALE presented at H2020 Innovation Forum

On October 4th, 2018 SCALE took part in the first H2020 Innovation Forum, a clustering event, bringing together H2020 projects, but also policy makers, end-users and industry representatives, material producers, private and public investors, start-ups and innovative SMEs. Thymis Balomenos from Aluminium of Greece, project co-ordinator, presented SCALE within the context of the clustering session, to an audience comprised by other H2020 projects,

Critical raw materials data management and European scandium inventory workshops

The German Federal Institute for Materials Research and Testing (BAM) in cooperation with the SCALE Project, is organizing a workshop on secondary raw materials/ urban mining data management in close connection with a scientific exchange platform for stake holders of the European scandium inventory.

Scandium is a chemical element with symbol Sc and atomic number 21. A silvery-white metallic d-block element, it was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.

Scandium is a chemical element with symbol Sc and atomic number 21. A silvery-white metallic d-block element, it was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.