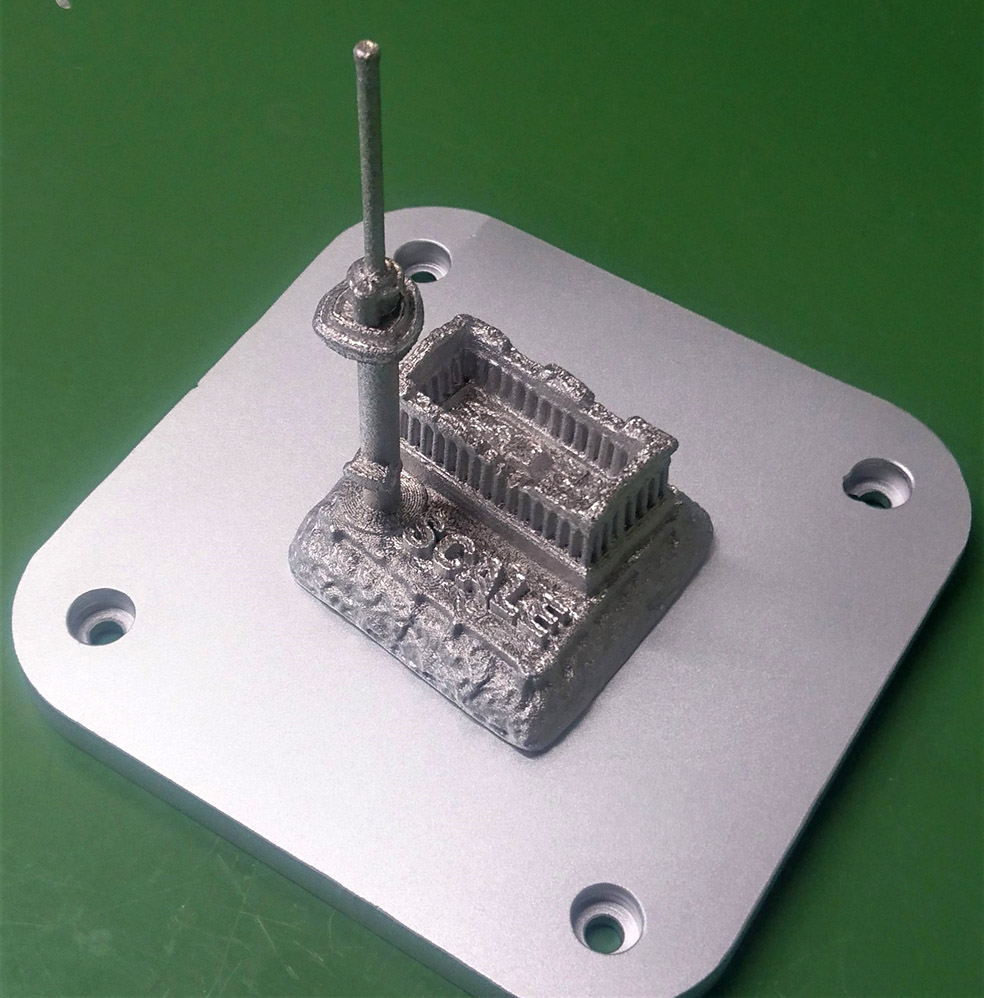

Following the successful demonstration of Al-Sc alloy production at LCM, KBM proceeded with a demonstration of the additive manufacturing technology. Al-Sc master alloy was processed at KBM cast house to produce SCALM alloy (Al-Sc-Mg). The SCALM alloy was atomized, i.e. transformed into metallic powder, which in turn was used to fuel a lazer 3D printer. The resulting model depicts landmarks from Athens and Rotterdam, with incredible detail. Compared to traditional mold casting, such additive manuftacturing has the followinwg advantages:

- Rare Shape-Making Ability

Additive manufacturing is very attractive for unusual or complex component shapes that can be difficult to manufacture using other processes. Design software makes it possible to create nearly any geometric form, such as hollow spaces or honeycombs, that maintain stability while decreasing weight. - Manufacturing & Assembly in 1

An additive manufacturing line can produce multiple components at a time. Instead of creating individual parts and assembling them at a later point, an additive manufacturer can combine manufacturing and assembly into a single process.

This cuts down on what would otherwise be an extraordinary lead time. - Even Less Waste

Additive manufacturing almost always involves less waste material. Traditional manufacturing processes typically involve removing product from a larger workpiece, while AM actually adds product from scratch to create your component. Using only the material necessary to create a part ensures minimal waste

Comments are closed.

Scandium is a chemical element with symbol Sc and atomic number 21. A silvery-white metallic d-block element, it was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.

Scandium is a chemical element with symbol Sc and atomic number 21. A silvery-white metallic d-block element, it was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.